On average one million Canadians are injured, or become sick/diseased by their workplace each year. About 10% will result in a brain injury. 95% of these workplace injuries were preventable.

However, workplace brain injury rates are sketchy at best, as many head injuries go unreported, or are considered as part of another injury.

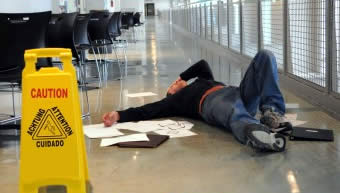

Of workplace accidents, slips, trips and falls are a major cause of injury to approximately 60,000 Canadian workers each year. These preventable accidents may result in bruises and abrasions, broken  limbs, cracked ribs, serious back and brain injuries, and sometimes even death. While the image of an employee falling is generally someone tumbling from some type of elevation (such as from a ladder), the truth is that most falls occur on the same level. In fact, “same level” falls account for 65% of all fall-related injuries, 20% of all workplace injuries, and about 80% of all occupational brain injuries.

limbs, cracked ribs, serious back and brain injuries, and sometimes even death. While the image of an employee falling is generally someone tumbling from some type of elevation (such as from a ladder), the truth is that most falls occur on the same level. In fact, “same level” falls account for 65% of all fall-related injuries, 20% of all workplace injuries, and about 80% of all occupational brain injuries.

Age may also play a factor in workplace injury rates and severity. Statistically, young people and new hires are more at risk of injury on the job. Among injured employees under the age of 25, more than 50% were hurt within the first six months on the job, with nearly 20% of all workplace injuries and fatalities happening during the first month on the job.

However, while young workers are known to have more injuries in the workplace, when older workers are injured it tends to be more serious. And, injury severity and rate are also often affected by the person’s sex. While men were more likely to die from a workplace injury, women were much more likely to require emergency medical attention and suffer long term effects.

Occupation also seems to play a significant factor in injuries as well. For instance; women who work in the health care sector are statistically three to four times more likely to incur a serious injury as men working in the same industry.

A great way to begin preventing brain injury at work, is to make yourself aware of the parts of the body that are most commonly injured. They are the: Eyes, Ears, Lungs, Hands, Feet, Legs, Spine, Head (brain), Bones and Skin.

Injury to any of these areas may compromise an employee’s balance, reaction times, skills and abilities, and can make them up to seven times more likely to experience another injury.

To protect yourself and others, please make it habit before entering a work area to assess for possible hazards. Always be aware that there may be unseen obstacles or slippery surfaces present, which may dramatically increase the risk of injury.

There are five basic types of workplace injury hazards to look for, and each of them have the potential to directly, or indirectly lead to a brain injury. They are:

There are five basic types of workplace injury hazards to look for, and each of them have the potential to directly, or indirectly lead to a brain injury. They are:

- Chemical hazards

- Physical hazards

- Biological hazards

- Muscle strain or musculoskeletal injury hazards

- Psycho-social hazards

Workplace safety is much more than merely protective measures, it is an attitude. Taking ‘shortcuts’, being over-confident, and becoming impatient at work are all major causes of injury. Bypassing steps and disregarding procedures, thinking that it ‘can’t happen to me’, and rushing to get things done are taking unnecessary risks that endanger your life, and possibly the lives of others. So please, slow down, be sure, and be safe.

We suggest you use the acronym “SAFE”, which stands for;

We suggest you use the acronym “SAFE”, which stands for;

Spot the hazard.

Assess the risk.

Find a safer way.

Employ safe practices.

A great start to safety is making sure you use appropriate workplace personal protective equipment (PPE) at all times. This equipment is designed to protect from workplace hazards, and includes, but is not limited to, safety glasses, goggles, face shields, respirators, hard hats, safety shoes, gloves, coveralls, vests, earplugs, safety straps and anchoring lines. Be sure that you have the right safety equipment for the job, know how to use it, and it is always used. For instance, people often remove hard hats and reflective vests before leaving the job site, but all protective gear should always be worn until the workplace has been exited.

A common contributing factor to workplace injury is poor footwear. Always use footwear with good traction in your personal life, and at work, Be sure to choose footwear that is appropriate for the work being performed (for example, do not wear high heels when climbing ladders, or running shoes to work in mud). Throw out old and worn footwear.

One of the most important things that you can do to protect yourself from a brain injury, especially at work, is to protect your head. Unlike an injury such as a broken arm or leg, which normally heals in a matter of weeks, an injured brain can take years to heal, and may leave you permanently disabled.

To protect the brain, wear proper protection for the job or activity. The most common types of workplace helmets used to protect the head are:

To protect the brain, wear proper protection for the job or activity. The most common types of workplace helmets used to protect the head are:

Type 1 – has a full brim (the brim fully encircles the dome of the hat). This type of helmet provides protection strictly from blows to the top of the head.

Type 2 – has no encircling brim, but may have a short bill on the front – This type of helmet provides protection from blows to both the top and sides of the head. Below are common helmet designations and classes according to the ANSI standard under which they were approved.

For Impact and Low Voltage electrical protection: ANSI Z89.1-1986 Class A, or ANSI Z89.1-1997 and 2003 Class G (General)

For Impact and High Voltage electrical protection: ANSI Z89.1-1986 Class A, or ANSI Z89.1-1997 and 2003 Class E (Electrical)

For Impact protection only: ANSI Z89.1-1986 Class C, or ANSI Z89.1-1997 and 2003 Class C (Conductive)

Despite the use of protective gear, awesome company safety policies, and aggressive accident reduction measures, many workplace injuries still occur because people simply do not pay attention. This lack of attention causes people to walk into obstacles or danger, slip on wet floors, trip over clutter, and stumble on irregular walking surfaces.

These types of workplace injuries can easily be prevented through safety education, awareness and preparation.

To reduce risk of workplace injury, make yourself aware of potential workplace dangers, such as:

Obstructed visibility – Impaired or obstructed vision is extremely dangerous. Make sure you have a clear line of site around the work area where possible, and constantly watch for potential danger.

Lighting – Ensure good lighting and visibility; replace burned-out bulbs when and where needed.

Elevation changes – Even a slight difference in surface elevation may cause possible imbalance, and/or present a trip hazard.

Chemicals/noxious fumes/toxic materials – Make sure work areas are well ventilated, and employ airway and skin protection. Be sure that there are no noxious fumes present that may cause loss of consciousness, or compromised balance and ability. Also be aware of long-term risks associated with exposure to lead paints and/or asbestos.

Chemicals/noxious fumes/toxic materials – Make sure work areas are well ventilated, and employ airway and skin protection. Be sure that there are no noxious fumes present that may cause loss of consciousness, or compromised balance and ability. Also be aware of long-term risks associated with exposure to lead paints and/or asbestos.

Elevated hazards – A common cause of workplace brain injuries are elevated, protruding, and /or hanging objects that people may strike their head on. Stay very aware of these dangers, and warn others to watch out for them as well.

Spills – Clean up spills immediately using appropriate clean-up procedures. If the spill is toxic, follow the safety procedures in the material’s safety data sheet.

Heat hazards – Always be cautious when using heat or fire of any kind on the job site. Each year many workplace injuries occur from hot exhaust airflow, heated equipment surfaces, scalding fluids and open flame. Be sure all dangers from heat sources are clearly labelled and identified, always use proper protection equipment, and do not place potentially combustible matter near heat sources. Make sure that work site clothing is flame retardant.

Ice/snow – Keep walkways free of ice and snow, and use salt or sand to improve traction on slippery surfaces.

Throw rugs/mats – Use only non-slip rugs and mats, making sure they are in excellent condition.

Wet areas – Always be very careful on wet and slippery surfaces. Be sure to place warning signs to identify areas of risk so people are aware of the possible danger(s).

Sharps – Use protective equipment and extreme caution when handling broken glass, blades, knives and other sharp objects. Dispose of sharps in a container with hard walls that cannot be punctured by sharp objects and pieces.

Clutter – Keep work areas organized and clutter free. Make sure that all trash and scrap materials are cleaned up, and disposed of in proper containers

Noise – Excessive noise may inhibit communication, and present immediate and long term danger. Always adequately protect your hearing, and stay very aware of activities in the work area.

Electrical hazards – make sure there are no power cords running through fluids, bare or exposed electric wires, and that all cords are properly grounded.

Electrical hazards – make sure there are no power cords running through fluids, bare or exposed electric wires, and that all cords are properly grounded.

Stairs – Keep stairways free from obstructions of any size. Often the smallest items on stairs present the greatest danger. Never store things on steps.

Tools – Lock down large tools when not in use, or while servicing. Return all small and hand tools to their proper designated storage areas.

Boxes and drums – Store stacked boxes and drums on a firm foundation, placed properly to prevent collapse and/or falling. Strap items together to prevent slippage.

Cords, cables and hoses – Be careful how you route and secure electrical cords cables and hoses, especially where they cross aisles. When storing, bundle properly and store in the designated manner, and in the designated area.

Empty containers and pallets – Keep stored safely in a designated area. Single pallets may use less space when stored on their ends, but need to be secured to a wall or structure to prevent them from falling.

Body fluids – Emergency first aid requires quick response, but always take time to use protective barriers from body fluids whenever possible (gloves, glasses/goggles, masks, sheeting, etc.).

Clothing hazards – Drawstrings and cords on hoodies, sweatshirts and coats can strangle you, be a trip hazard, or get caught in, on or by equipment, causing you to be pulled into machinery. Cut off or secure all items that may get snagged by machinery, or that may become a trip hazard (such as untied shoelaces).

Crushing Hazards – Be aware of, and keep away from moving objects and equipment, and/or any items that may fall and crush. Keep your limbs clear of all danger, and always be sure to shut down and lock all equipment before servicing.

You can also help prevent injuries in the following ways:

- Put smart phones, cell phones and digital devices in a locker to avoid any possible distraction while at work, and avoid all use while on the job.

- Lock doors and restrict access to all dangerous areas.

- Avoid eating or drinking on the job, except during authorized breaks in authorized areas. Never work with objects in the mouth.

Install window guards to prevent accidental falls. Do not place furniture, including chairs, close to windows. Make sure windows are closed and locked securely when not in use.

Install window guards to prevent accidental falls. Do not place furniture, including chairs, close to windows. Make sure windows are closed and locked securely when not in use.- Use furniture as intended. Never stand or kneel on furniture. All freestanding furniture and equipment, regardless of height, has the potential to tip and fall. No matter what the size, price or quality, always properly anchor furniture and equipment.

- Electrical outlets and equipment can present shock hazards. All electrical equipment and outlets should be kept in good condition, and be inspected on a regular basis. Use GFIC (Ground Fault Intercept Circuits) in all bathroom and kitchen outlets.

- Blind and curtain cords need to be shortened or removed so they do not present a trip, choke or snag hazard.

- All equipment and storage areas, such as commercial fridges, freezers, washers and dryers, should have interior handles to unlock the doors to prevent personnel from becoming locked inside.

- Keep audio visual equipment secured on stands/in cabinets. Flat screen televisions and monitors should be properly secured to walls, and/or in positions that do not present fall hazards.

- Keep all industrial tanks, pools and/or ponds gated and locked, with dangers clearly posted, along with emergency measures to be taken in case of an accident. Liquid hazards should be covered with proper protective covers, and never work alone in or near any size tank, pool or pond. Consider purchasing aquatic water movement alarms (alarms set off by fluid movement).

- Before operating a vehicle, always do vehicle walk-arounds to check the area for persons and equipment that may not be seen by shoulder checks of the use of mirrors.

- Never operate machinery or equipment while sick, or under the influence of alcohol and/or drugs.

- Always keep emergency phone numbers, including the number for the Poison Control Center, by all work site telephones.

- Ensure that all workers know CPR and basic first aid.

- Insure that all workplace equipment is turned off and properly secured when not supervised or in use.

To recap, the three primary ways to make a situation safer are:

- Identify the risk.

- Avoid the risk.

- Reduce/eliminate the risk.

If you, or someone else is injured on the job, be aware that you have a duty to report the injury and circumstances. It is important because you may not be aware of how bad the damage is, or possible long term effects. Reporting accidents assures that required emergency medical attention is received and documented, and that the injured person has been made aware of compensation eligibility for lost wages, as well as for therapies and/or treatment. Reporting injuries also helps employers to prevent future accidents to prevent similar injuries from happening to others.

If you, or someone else is injured on the job, be aware that you have a duty to report the injury and circumstances. It is important because you may not be aware of how bad the damage is, or possible long term effects. Reporting accidents assures that required emergency medical attention is received and documented, and that the injured person has been made aware of compensation eligibility for lost wages, as well as for therapies and/or treatment. Reporting injuries also helps employers to prevent future accidents to prevent similar injuries from happening to others.

The bottom line is that there is simply no substitute for workplace safety. Staying safe at work and at play is a win-win situation for everyone. Workplace safety reduces costs to taxpayers, to employers, and minimizes pain and suffering. So please, always do whatever you can to keep yourself and others safe.